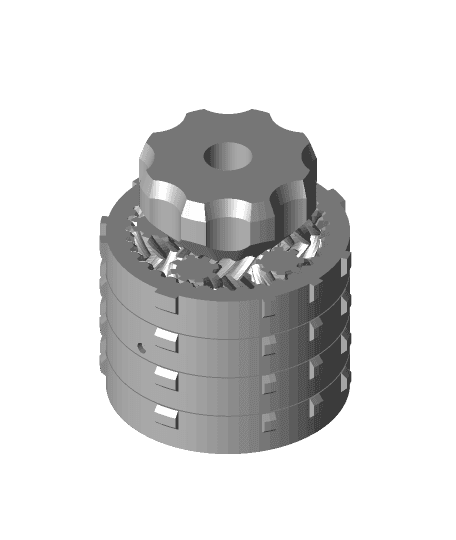

Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4034834.

Not much of a puzzle, really. Just turn the knob.

Print in place, fully assembled, no supports. Just be sure to have your tolerances dialled in and your slicer preserves the one-layer gap in the outer ring gears. After printing, remove core and separate ring gears with something sharp like a spatula or razor blade.

Update: Increased tolerances from initial version. Should print fully assembled but I'd still recommend printing core and shell separately for smoothest finish which is important for sliding.

Updated math, verified by reality...

Gear ratios relative to top (fixed) gear: (formulas included in scad) P1 P2 R1 R2 S1=2P1 S2=2P2 Gear Ratio 8 5 34 20 16 10 1:50 8 6 34 23 16 12 1:28.75 (4:115=5x23) 8 7 34 26 16 14 1:21.6667 (3:65=5x13)

We can forget the fractional turns, since it must at least be a multiple of 50 (a whole number) giving us a lowest common multiple of 50x13x23 = 14950

So that 14950 turns of input knob gives: 14950/50 (299 turns of first layer) 14950x4/115 (520 turns of second layer) 14950x3/65 (690 turns of third layer)

By my reckoning, 14950 turns are required for a complete cycle, this is demonstrated in the accompanying video. That's lower than it could be since all layers share a common factor of 5 in this case (probably due to having 5 planets).